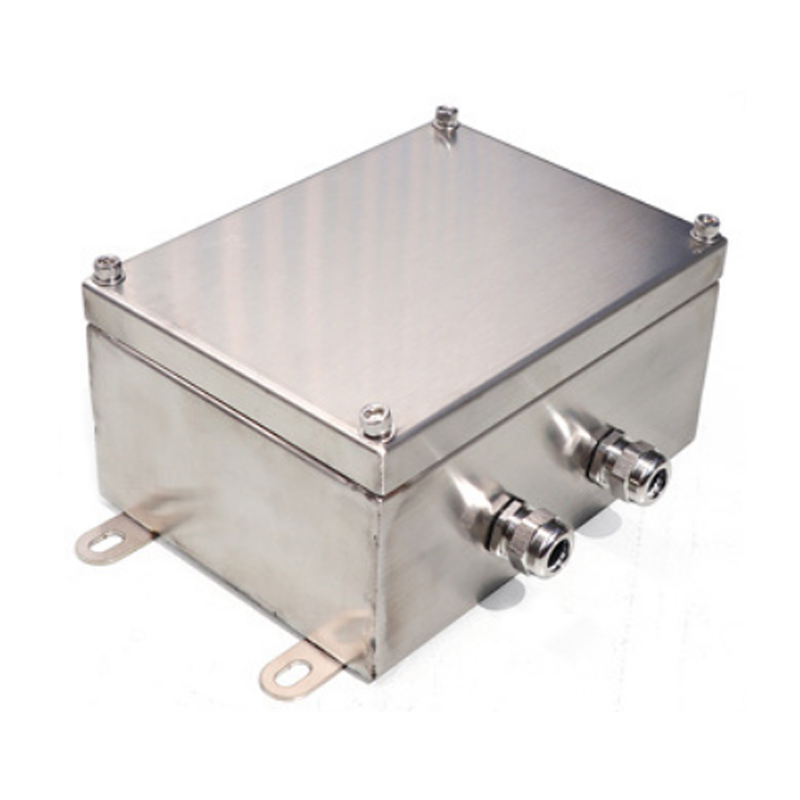

Stainless Steel Electrical Junction Enclosure Box

Stainless steel junction boxes are used for wall switch boxes, which can be sturdy, stable, anti-aging, corrosion-resistant, rust resistant, explosion-proof and more durable than PVC switch boxes. The lifespan of PVC material switch boxes will gradually age during use and cannot withstand long-term use with the same lifespan as the house.

Specification:

| 1.Material: | stainless steel 304,316 | |||||

| 2.Product name: | stainless steel junction box | |||||

3Dimension: | 150*150*100mm,200*150*100mm and also can be custom made. | |||||

| 4.Optional surface treatment: | Polished, brushed. | |||||

| 5.Sample Making : | Free standard sample and Rapid prototype according to customer's drawing. | |||||

| 6.Quality Guarantee: | Pre-production sample validation -Inspection in production process-Final inpesction. | |||||

| 7. Certificate of Quality system: | ISO9001 : 2015, IATF 16949 : 2016 | |||||

Material: Typically made of steel, aluminum, or stainless steel for durability, corrosion resistance, and electromagnetic shielding.

Protection Ratings:

IP (Ingress Protection): Common ratings like IP65 (dust-tight and water-resistant) or IP66 (high-pressure water jets).

NEMA Standards: NEMA 4 (weatherproof) or NEMA 12 (dust/oil-resistant).

Design: Includes mounting options (flanges, DIN rails), ventilation slots, hinged/lockable doors, and cable entry points (glands or knockouts).

Industrial Control Panels: Houses PLCs, relays, and circuit breakers.

Power Distribution: Used in switchgear or transformer enclosures.

Outdoor Installations: Protects against weather (e.g., traffic signal controls).

Residential/Commercial: Conceals wiring or meters (e.g., junction boxes).

Environment: Choose stainless steel for corrosive areas (e.g., chemical plants).

Size: Ensure internal space accommodates components with room for heat dissipation.

Safety Compliance: Meets standards like UL 508A (industrial controls) or IEC 61439 (low-voltage assemblies).

Pros:

Superior durability and fire resistance compared to plastic enclosures.

EMI/RFI shielding for sensitive electronics.

Cons:

Higher cost and weight than plastic.

Requires grounding to prevent electrical hazards.

Regularly inspect for rust (apply coatings if needed).

Ensure seals/gaskets are intact to maintain IP ratings.

Label internal components for easy troubleshooting.